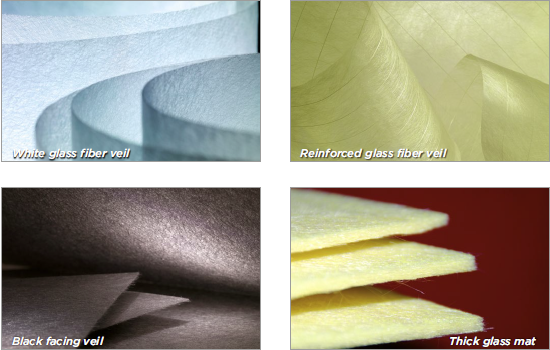

GLASS VEILS

Specification

Wet laid glass veil process

Wet chopped glass fibres are dispersed in a water based solution. The solution is poured onto a moving wire mesh belt. The damp veil is then passed under a binder applicator where liquid resin binder is applied. The veil then passes through an oven to be dried.

Dry laid glass veil process

The fibres are produced directly from a furnace that is above the conveyor belt where the veil is formed. The second part of the process remains similar to the wet

Wet laid & dry laid glass fiber veils - From 25 to 700 gr/m2 - In white, yellow or black colour - With or without

reinforcement by longitudinal yarns - Binders: acrylics, urea formaldehyde, melamine & bio-sourced binders.